Maintenance

-

It allows based on statistics to plan preventive maintenance to reduce the risk of equipment failure.

-

Helps you automate the maintenance process by calculating the average failure time and average repair time, so you can approximate the date of the next failure of the equipment used.

-

It allows the request and planning of maintenance by the employees of the machines, equipment, etc. within your company.

-

Facilitates the production process and increases performance through good communication with the production department.

-

Performs direct communication with the Production, Repair, and Calendar modules.

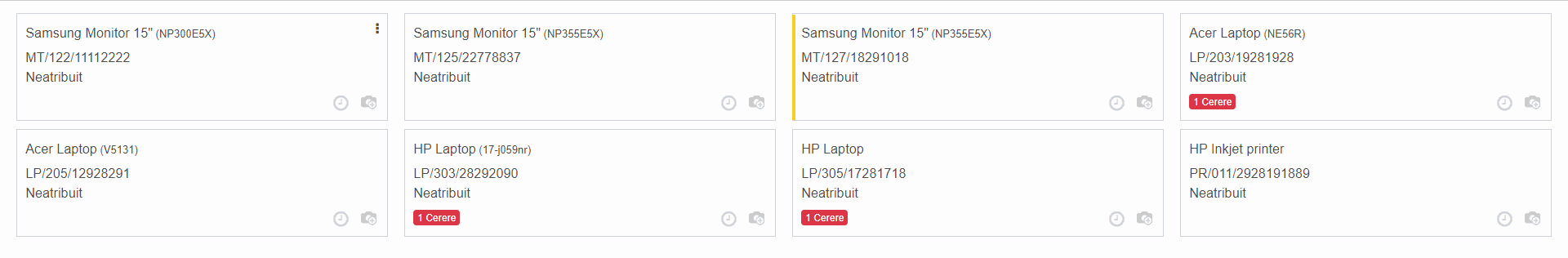

Overview of the equipment

You can view all the equipment and maintenance requests, as well as their current status: repaired, scrap, etc.

An overview of the equipment within your company is available.

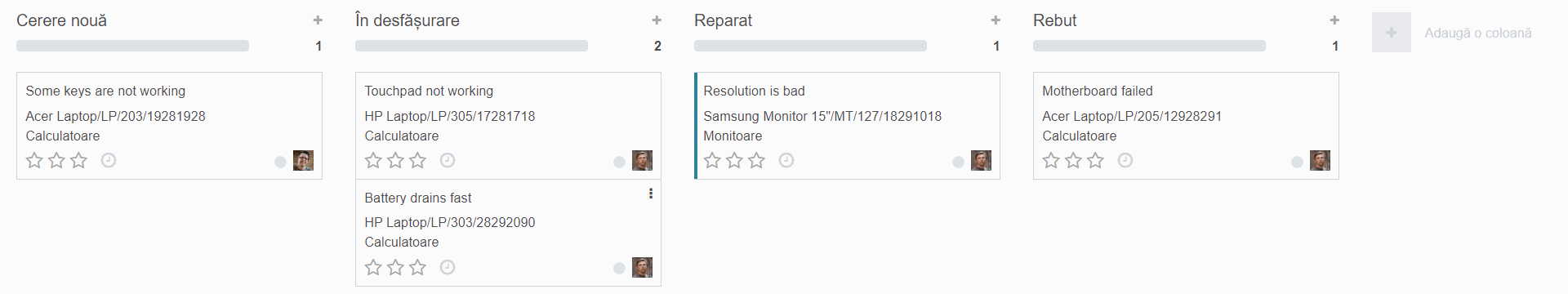

Scheduling maintenance

Organization of maintenance stages

The module allows the organization of maintenance in a simple way to use, using drag & drop.

You can view all maintenance requests, as well as their current status: new request, in progress, repaired, scrap etc.

An overview of maintenance requests within your company is available.

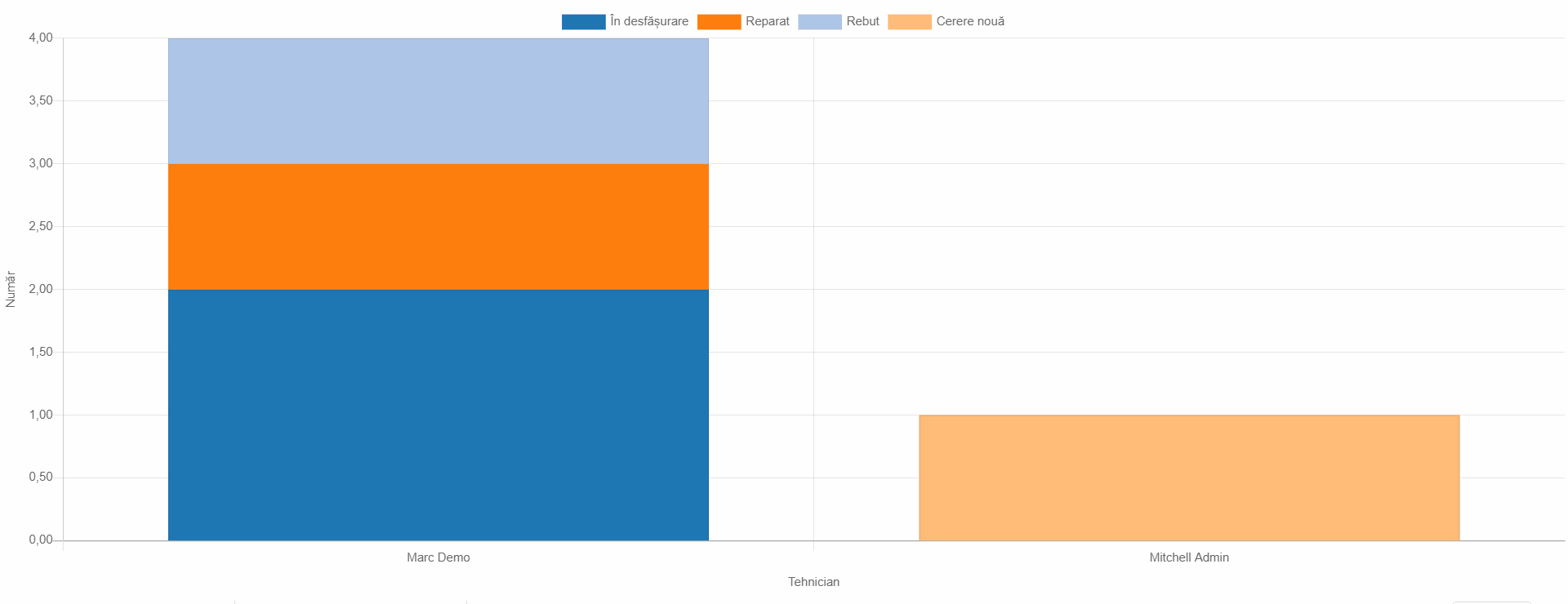

Analysis of maintenance requests

This module allows you to view the analysis of the performance of the maintenance team, according to different criteria such as the number of maintenance requests in a year, a month, etc.